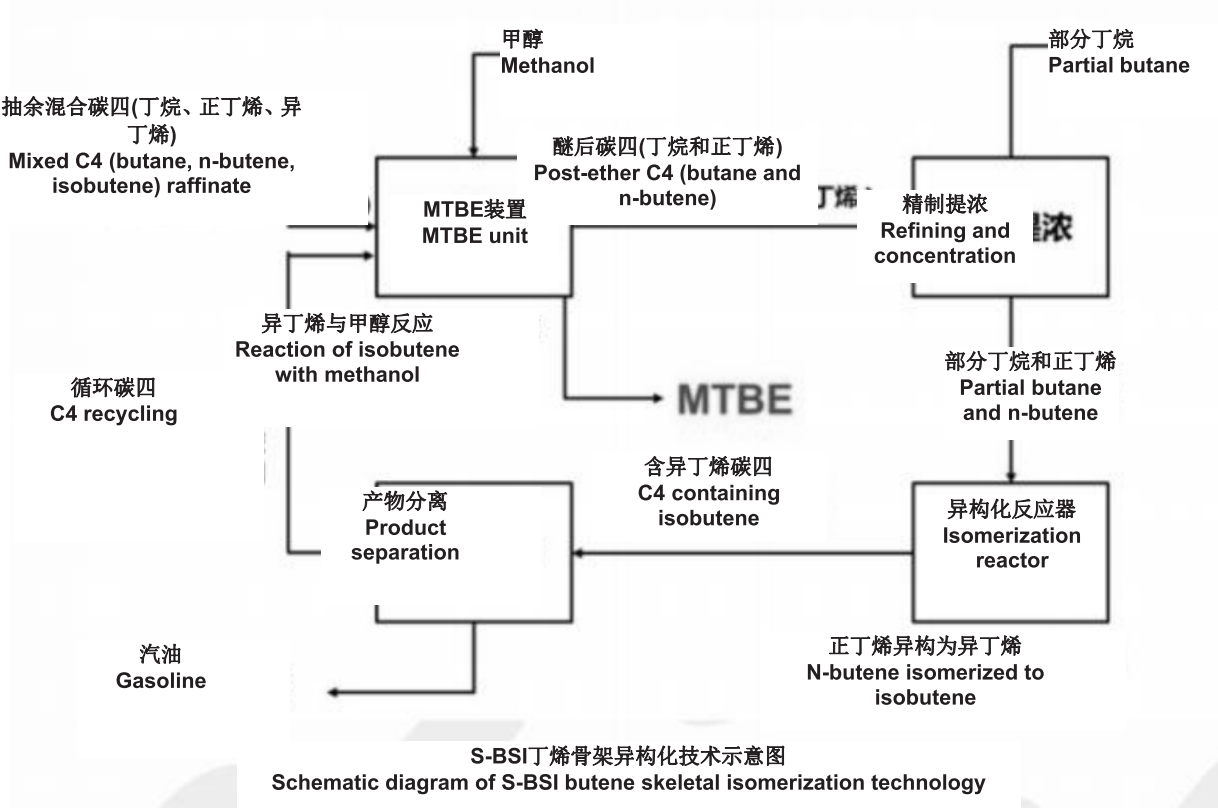

Overview:

The catalyst utilizes butene as a feedstock to produce isobutene (normal butene) through skeletal isomerization. Isobutene serves as a precursor for the production of methyl tert-butyl ether (MTBE), primarily used as an additive in clean gasoline to enhance octane ratings. Since 2004, comprehensive research on butene skeletal isomerization technology has been conducted, resulting in the successful development of the fully crystalline FER zeolite series catalysts. The project has accumulated more than ten Chinese patent applications.

Butene Skeletal Isomerization Technology:

This process, using C4 feedstock rich in butene to produce isobutene, features:

1. Extremely low energy consumption: With a gas hourly space velocity (GHSV) reaching above 2.0, energy consumption and equipment investment are significantly reduced.

2. Outstanding product quality: Highly selective catalysts minimize by-products, ensuring high isobutene content.

3. Maximum feedstock flexibility: Catalysts demonstrate strong tolerance to impurities, compatible with polymer-grade, chemical-grade, and refinery-grade butene.

4. No hydrogen required: The process operates without hydrogen, simplifying operations and enhancing economic viability.

Butene Skeletal Isomerization Series Catalysts:

The primary promoted brand of butene skeletal isomerization catalysts showcases the following characteristics:

1. High activity: Catalysts enable high butene conversion rates with extended intervals between unit temperature increases.

2. High selectivity: Low production of by-product isomerate oil, high isobutene selectivity, and efficient butene utilization significantly improve overall plant economics.

3. High stability: Single-pass lifespan reaches three months, with stable regeneration performance and an expected catalyst lifetime of two years.

4. Eco-friendly: Free from toxic and corrosive components, these catalysts are environmentally friendly and reusable.

5. High mechanical strength: The catalysts possess high crush resistance, fulfilling industrial application demands.

Application and Dissemination:

The isomerization catalyst has been implemented in industrial applications, including a 320,000-ton/year n-butene isomerization unit in Guangdong and a 130,000-ton/year isobutene isomerization plant in Ningxia