Overview:

Propylene oxide (PO) is a raw material for producing polyether polyols, which are further used in the production of polyurethane. The technology for producing propylene oxide is based on the use of propylene, cumene hydroperoxide (CHP), air, and hydrogen as raw materials, through the oxidation of cumene, epoxidation of propylene, and hydrogenation of dimethylbenzyl alcohol (DMBA) to produce propylene oxide, with cumene being recycled to produce epoxy propane. Since 2003, comprehensive research has been conducted on the synthesis technology of PO, and high-performance mesoporous propylene epoxidation catalysts containing titanium and bifunctional DMBA hydrogenation catalysts with superhydrophobic characteristics have been successfully developed. Based on these catalysts, a green and environmentally friendly PO synthesis technology with atomic economy reaction characteristics has been successfully developed.

The project has accumulated 43 authorized invention patents in China and won the second prize of Sinopec's forward-looking basic research science award.

Epoxy Propane Synthesis Technology:

Epoxy propane technology is a green and environmentally friendly PO synthesis technology with atomic reaction economy characteristics. A 150,000 tons/year PO industrial demonstration plant will be built in Tianjin Petrochemical, with the following technical features:

1. Safe and efficient epoxidation reaction system: Multi-stage series, inter-stage heat withdrawal for propylene epoxidation reaction and control system; higher concentration of CHP raw materials and lower propylene/CHP ratio can be used to reduce energy consumption; according to the different reaction activity of catalyst life cycles, the reactor arrangement sequence is reasonably arranged to ensure sufficient conversion of CHP and eliminate safety risks.

2. Efficient and energy-saving hydrogenation reaction system: The dehydration and hydrogenation of dimethylbenzyl alcohol are effectively coupled, and a bifunctional Pd-based hydrogenation catalyst has been successfully developed. According to the characteristics of the bifunctional catalyst, a two-stage hydrogenation process is cleverly designed to achieve high selectivity and high conversion of the catalyst, significantly reducing the loss of cumene.

3. Efficient product refining process and excellent product quality: Organic acid enrichment-alkali washing/water washing process, using efficient alkali washing/water washing equipment to effectively remove organic acids from a small part of the reaction liquid products, reducing the loss of PO in the alkali washing process. A PO extraction distillation process and extractant purification process have been developed to improve the purity of the circulating extractant and PO yield, with PO product purity reaching over 99.99%.

Epoxidation and hydrogenation catalysts:

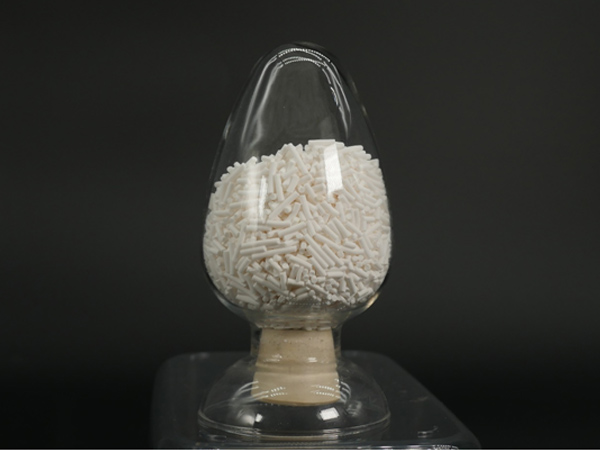

Epoxy propane synthesis technology includes two types of catalysts: superhydrophobic Ti/HMS epoxidation catalyst and bifunctional Pd-based hydrogenation catalyst.

The main features of Ti/HMS epoxidation catalyst are as follows:

1. Excellent catalytic performance: For the first time, based on biomimicry principles, a highly efficient titanium-containing mesoporous molecular sieve epoxidation catalyst Ti/HMS with superhydrophobic properties and super nanostructure and surface wax layer mechanism for producing PO from CHP oxidation of propylene has been developed.

(1) High activity: CHP conversion of Ti/HMS epoxidation catalyst reaches over 99%.

(2) High selectivity: Ti/HMS epoxidation catalyst achieves over 99% selectivity for PO and DMBA.

(3) High stability: Ti/HMS epoxidation catalyst has a lifespan of 6-12 months (compared to 4.5-9 months for similar products).

(4) Environmentally friendly: The catalyst contains no harmful or corrosive components, and does not pollute the environment.

The main features of the bifunctional Pd-based hydrogenation catalyst are as follows:

1. High activity: DMBA conversion rate of Pd-based hydrogenation catalyst reaches over 99%.

2. High selectivity: Pd-based hydrogenation catalyst achieves over 99.5% selectivity for cumene.

3. High stability: With a lifespan of over 2 years using bifunctional Pd-based hydrogenation catalyst, it maintains stable operation over long periods and retains its reaction performance during operation.

4. Environmentally friendly: The catalyst contains no harmful or corrosive components, and does not pollute the environment.

Application Promotion:

Epoxy propane synthesis technology has been licensed for a 150,000 tons/year PO industrial demonstration plant in Tianjin Petrochemical, which is under construction.